New Compound Materials Development

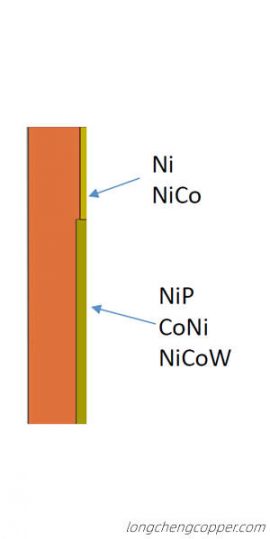

Method: Coating different materials in one plate.

Function: Improved the heat resistance of upper mould and wear resistance of lower mould.

| Customer | Size | Material | Coa7ng |

| Taiyuan Stainless Steel | 2420×900×45 | CuCrZr | Ni+ CoNi |

| Baosteel Zhanjiang | 2650×900×40 | CuCrZr | Ni+ CoNi |

| G-‐steel Thailand | 1986×950×35 | CuCrZr | Ni+ NiCo |

Longcheng Copper™

- Longcheng Copper™ brand is owned by RKO Group.

- Longcheng Copper™ is supplier in China that with complete production from raw material to the end products, and also involves all metallurgical equipment regarding con-casting.

- We are the drafter of National Standards (GB/T 26025-2010) “ Copper Mould Production of Steel Continuous Casting”.

- With more than 50 independent national and international patents.

- Production capability: Supplying 4,000 sets of new Copper Mould and 300 sets of Copper Mould Assembly per year. And we repairing more than 75% of total Chinese Copper Mould market for coating and machining.

- Involves all kinds of copper mould: Slab, CSP, FTSC, ISP, BB Mould, Billet etc..

- Our production covering 98% of total Chinese steel plants and takes 85% market share for the new copper mould.

Add New Comment